RIBER's MBE 8000 Elevates Epiwafer Manufacturing to New Heights

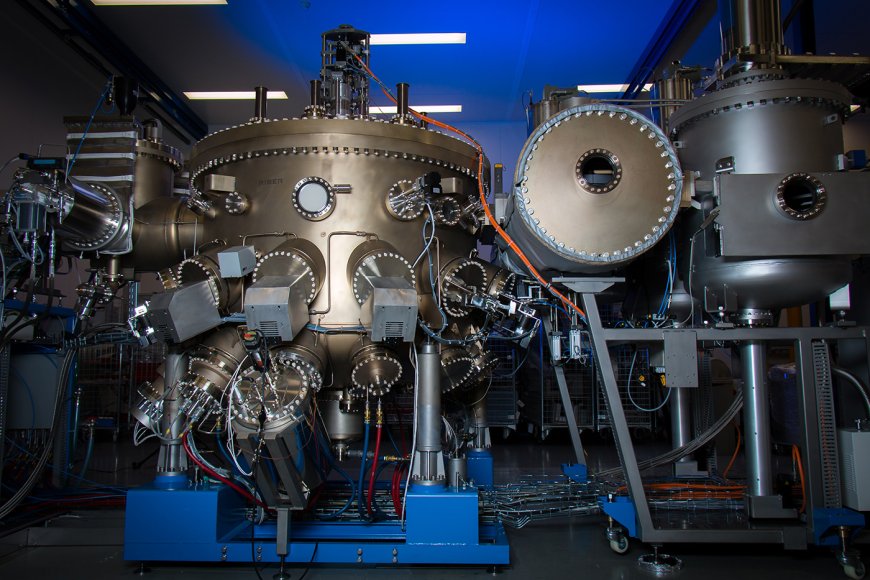

RIBER, a global leader in molecular beam epitaxy equipment, has announced the launch of the MBE 8000 system, offering unparalleled productivity and uniformity in epiwafer manufacturing.

In a significant development for the semiconductor industry, RIBER, the global leader for molecular beam epitaxy (MBE) equipment, has announced the launch of its MBE 8000 production platform. This system, having undergone its final qualification by a leading US epiwafer manufacturer, is poised to transform mass epiwafer production with its unprecedented capabilities.

The MBE 8000 distinguishes itself by offering double the productivity of existing products in the market. Its versatility lies in the flexibility of MBE technology, making it suitable for a range of compound semiconductor markets such as VCSEL, transistor, and sensors. These applications require high levels of performance in terms of uniformity, reproducibility, and stability, demands that the MBE 8000 is designed to meet.

A notable feature of the MBE 8000 is its capacity to grow batches of eight 150 mm (6 inches) or four 200 mm (8 inches) wafers, thereby increasing capacity by 50% compared to existing products. Its design maintains consistency with RIBER's existing systems in terms of cell design, system geometry, and process control. This ensures a seamless process transfer and straightforward handling for operators familiar with RIBER's machines.

The final qualification step for the MBE 8000 has solidified its status in terms of process robustness, stability, ergonomics, and control. A critical aspect of its performance is the defect density, which over 30 runs has been measured at less than 50 particles per cm² on a VCSEL-type structure, with particles in the size range of 0.8-8µm.

In addition to its robust design and high capacity, the MBE 8000 has achieved remarkable technical feats. These include the thickness uniformity of InGaAs/GaAs superlattices over the 8x6” platen, with a precision of 298Å ± 2 Å, and the Fabry-Perot dip uniformity of resonator wafers over an 8x6” platen at 3nm. Moreover, it has recorded HEMT electron mobility at 178,000 cm²V-1s-1 at 77K, showcasing the system's exceptional capabilities.

With an optimal cost of ownership and a significant increase in capacity, the MBE 8000 not only enhances the productivity of epiwafer manufacturing but also opens up new opportunities for business development in the semiconductor industry. Its introduction is a testament to RIBER's commitment to innovation and excellence in semiconductor technology.

The MBE 8000 system from RIBER represents a major advancement in the field of epiwafer manufacturing, offering improved productivity, precision, and potential for technological breakthroughs. This development is expected to have a substantial impact on the semiconductor industry, further solidifying RIBER's position as a leader in molecular beam epitaxy equipment.